Rotor Frequently Asked Questions

All Hunter Rotor models, including the PGM, SRM, PGJ, PGP, PGP Ultra and I-20, adjust the same way and utilize the same adjustment tool, the white Hunter wrench.

The instructions you see below, as well as in the Video, “PGP Rotors Adjustment Instructions”, use the PGP Rotor as an example.

Arc Adjustment

Adjustable heads are preset to approximately 180°. Sprinklers may be adjusted with water on or off. It is recommended that initial adjustments be made before installation.

Adjustable heads are preset to approximately 180°. Sprinklers may be adjusted with water on or off. It is recommended that initial adjustments be made before installation.

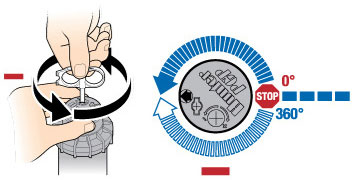

- Using the palm of your hand, rotate the nozzle turret counterclockwise to the left stop to complete any interrupted rotation cycle.

- Rotate the nozzle turret clockwise to the right stop. This is the fixed side of the arc. The nozzle turret must be held in this position for arc adjustments. The right stop does not change.

- If right stop position needs to be moved, please click the link below for video instructions on adjusting PGP rotor.

Radius / Distance of Throw

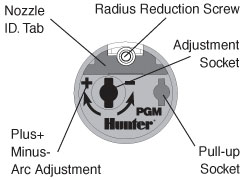

Insert the steel hex end of the Hunter wrench into the Radius Reduction Screw. Turn the screw clockwise to decrease the radius, or counterclockwise to increase the radius. Radius can be reduced by up to 25%.

Insert the steel hex end of the Hunter wrench into the Radius Reduction Screw. Turn the screw clockwise to decrease the radius, or counterclockwise to increase the radius. Radius can be reduced by up to 25%.

Caution for PGP-ADJ: Turning the adjustment screw clockwise more than five full turns may result in a lost radius adjustment screw.

To Increase the Arc

- Insert the plastic key end of the Hunter wrench (click here to purchase) into the adjustment socket

- While holding the nozzle turret at the right stop, turn the wrench clockwise. Each full 360° turn of the wrench will increase the arc 90°.

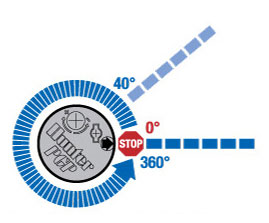

- Adjust to any arc between 40° or 50° and 360°

- The wrench will stop turning, or there will be a ratcheting noise, when the maximum arc of 360° (full circle) has been reached.

To Decrease the Arc

- Insert the plastic key end of the Hunter wrench into the adjustment socket.

- While holding the nozzle turret at the right stop, turn the wrench counterclockwise. Each full 360° turn of the wrench will decrease the arc 90°.

- Adjust to any arc between 40° or 50° and 360°.

- The wrench will stop turning, or there will be a ratcheting noise, when the minimum arc of 40° or 50° has been reached.